Key Specifications / Features

Model No.: Hits: 348

Quick Detail

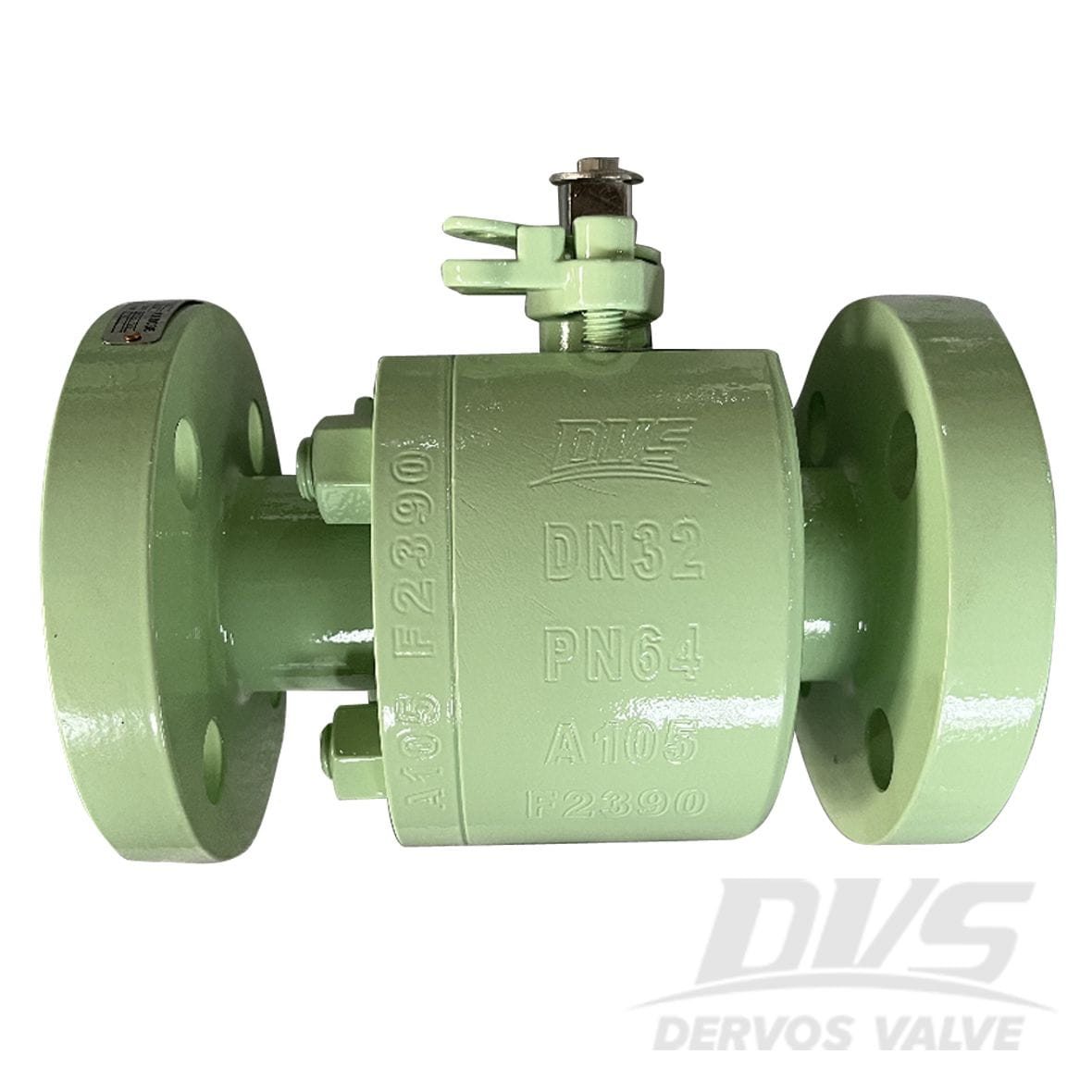

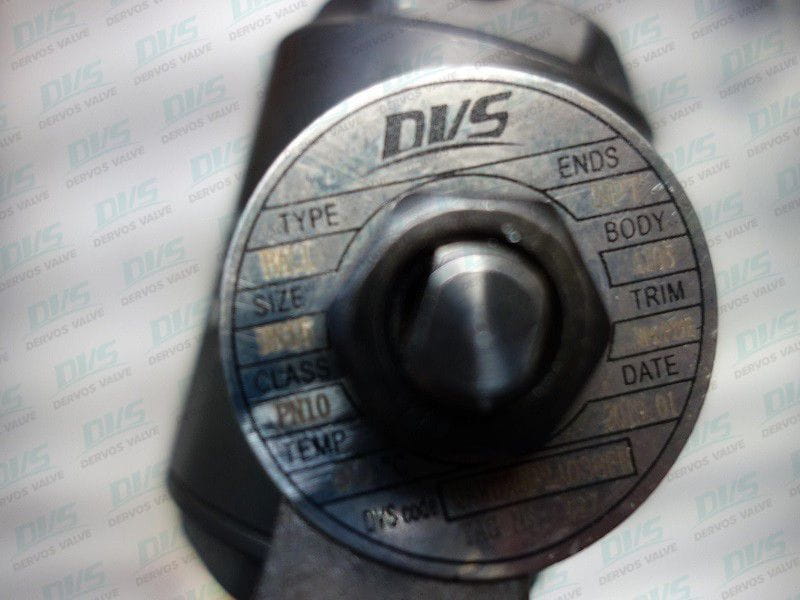

| Type | Ball Valve |

| Nominal Diameter | DN15 |

| Nominal Pressure | PN10 |

| Construction | 2-Piece type, Floating Ball, Reduced Bore |

| Connection | NPT |

| Design & Manufacture | ASME B16.34 |

| End to End Dimension | MFR |

| End Connection | ANSI B1.20.1 |

| Test & Inspection | API 598 |

| Fire Safe Test | API 607 |

| Body Material | A105 |

| Operation | Lever |

| Media | Water, Oil, Gas, etc |

Detail Information

Type: Ball Valve

Nominal Diameter: DN15

Nominal Pressure: PN10

Construction: 2-Piece type, Floating Ball, Reduced Bore

Connection: NPT

Design & Manufacture: ASME B16.34

End to End Dimension: MFR

End Connection: ANSI B1.20.1

Test & Inspection: API 598

Fire Safe Test: API 607

Body Material: ASTM A105

Operation: Lever

Media: Water, Oil, Gas, etc.

Product Range

The main features of a 2-piece forged steel ball valve are compact structure, reliable sealing, simple structure and convenient maintenance. The sealing surface and sphere are often closed, so it is not easy to be eroded by the medium and easy to operate and maintain. It is not only suitable for general working conditions such as water, solvent, acid and natural gas but also suitable for media with poor working conditions, such as oxygen, hydrogen peroxide, methane and ethylene. It is widely used in various industries.

Moreover, the 2-piece forged steel ball valve also has the following three characteristics:

1. Low fluid resistance: The cross-section of the connecting pipe between the sphere and the valve body is equal, when the medium passes through the sphere, the fluid resistance is small;

2. Good sealing performance: The valve seat adopts RPTFE material with certain elastic deformation and high strength to achieve good sealing performance and ensure the stability of the valve.

3. Long service life: The valve core is made of austenitic stainless steel and the valve seat material is RPTFE, which can achieve good corrosion resistance and prolong the service life of the valve.

Inspection

|

|

|

|

|

|

Keywords of ASME B16.34 Floating Ball Valve, ASTM A105, DN15, PN10

2 Pieces Full Pore Ball Valve

Forged Steel Ball Valve

Ball Valve DN15 PN10

Forged Steel Floating Ball Valve

A105 Floating Ball Valve