Key Specifications / Features

Model No.: Hits: 86

Quick Detail

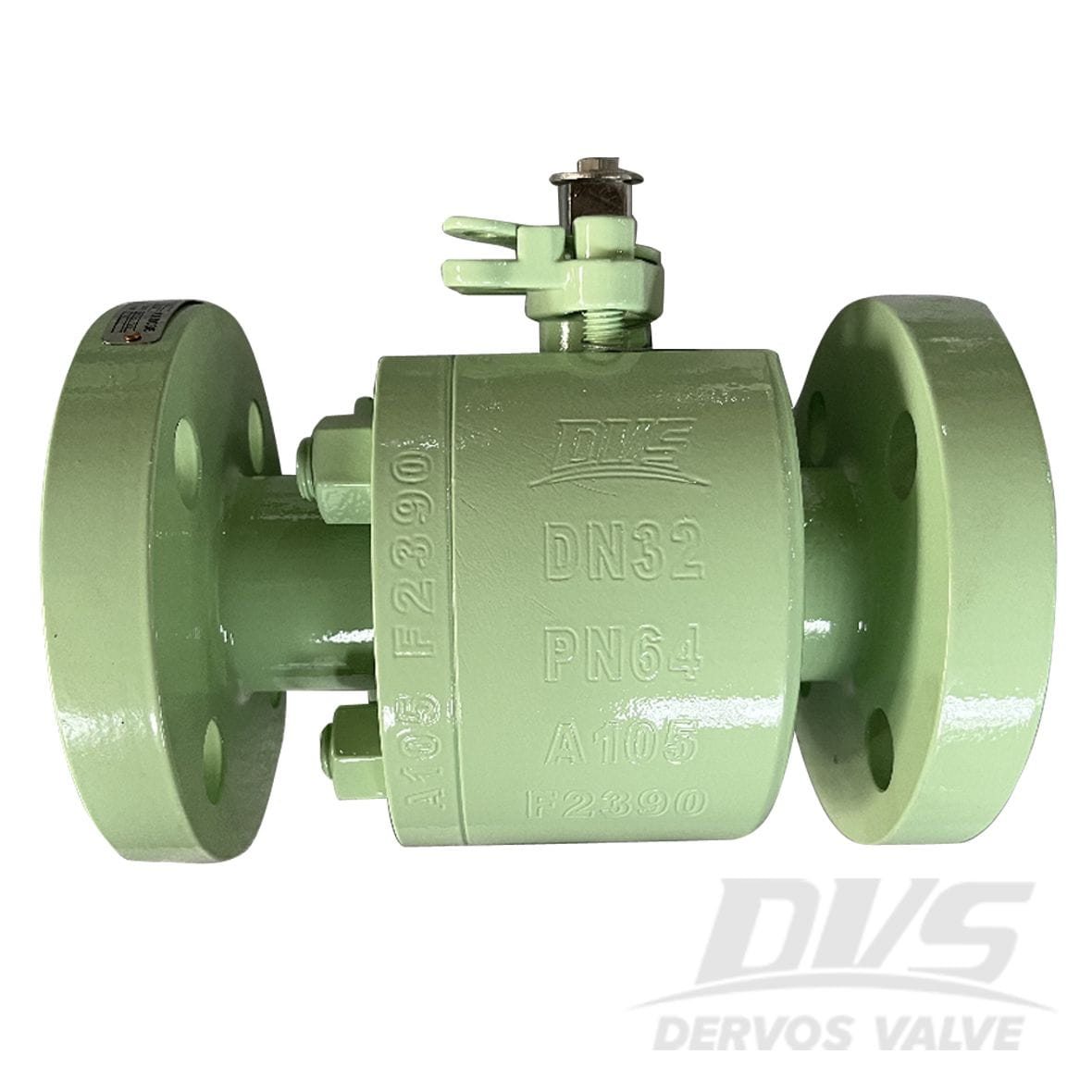

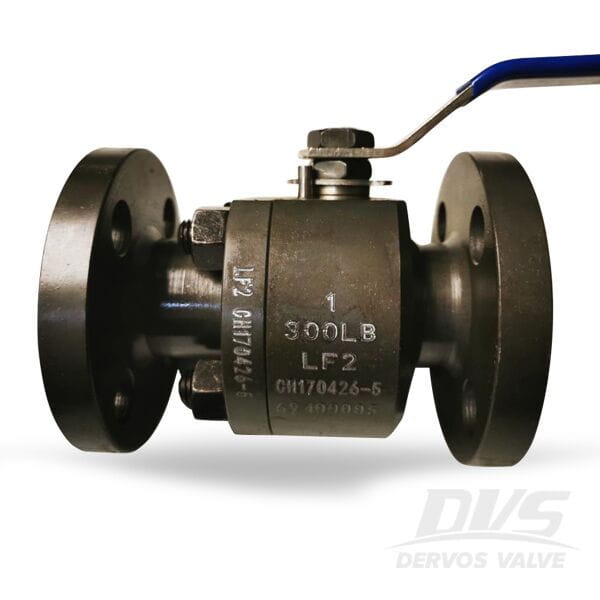

Type: Ball Valve

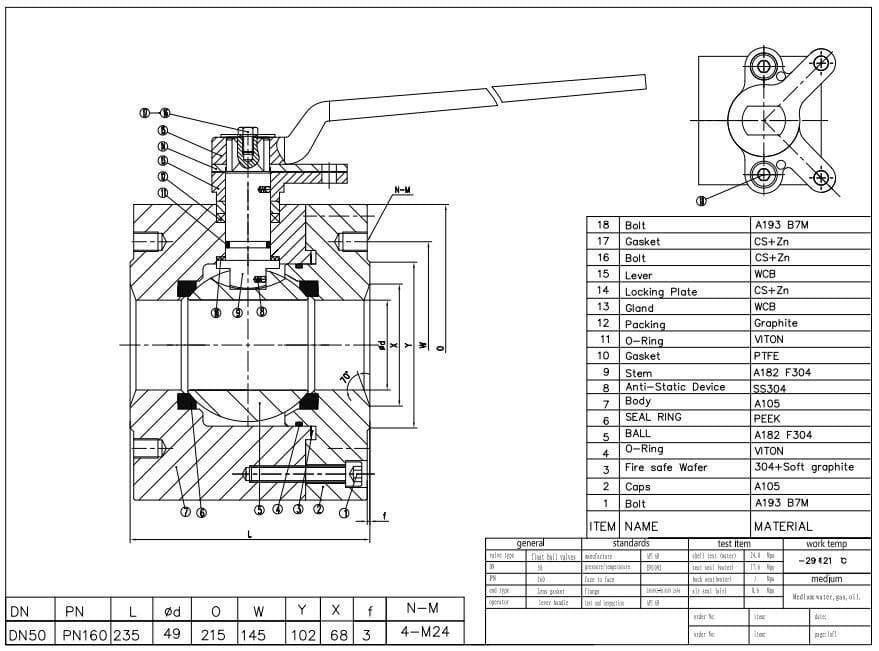

Size: DN50

Pressure: PN160

Construction: Floating Type Ball, Two-Piece Body, Full Bore

Connection: Lens Gasket

Operation: Lever Handle

Body Material: ASTM A105

Design Standard: API 6D

Pressure & Temp Code: EN 1092

End Connection: EN 1092-B1, DIN 2696

Inspection Code: API 6D

Temperature Range: -29℃ - 121℃

Media: Water, oil and gas

Detail Information

| Type | Ball Valve |

| Size | DN50 |

| Pressure | PN160 |

| Construction | Floating Type Ball, Two-Piece Body, Full Bore |

| Connection | Lens Gasket |

| Operation | Lever Handle |

| Body Material | ASTM A105 |

| Design Standard | API 6D |

| Pressure & Temp Code | EN 1092 |

| End Connection | EN 1092-B1, DIN 2696 |

| Inspection Code | API 6D |

| Temperature Range | -29℃ - 121℃ |

| Media | Water, oil and gas |

Features

--Preload between the seats during assembly.

--Seals incrementally tighter against the seats as pressure increases.

--Provides a reliable positive shut-off in either flowing direction.

--Quarter-turn design.

--Available as a manual lever, gear operated or actuated.

Product Range

Dimension Check

Witnessing Tests

Packing

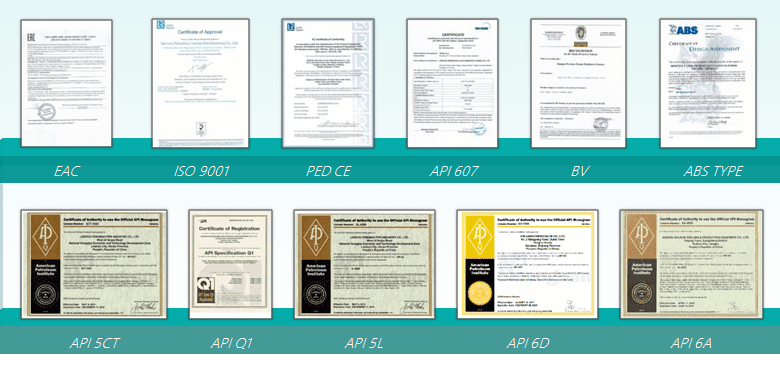

Certificates

Certificates are one of the factors our clients are caring about. At clients' request, we could provide API 5L, API 6A, API 6D, API 607, API 5CT, ISO 9001, PED CE and so on.

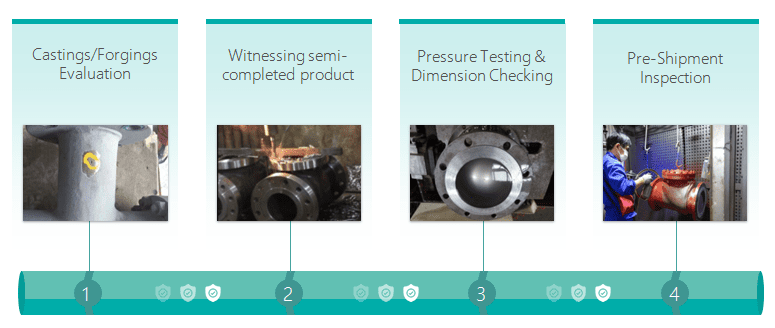

Dervos Quality Checking System

In Dervos, we control quality throughout the whole manufacturing process.

Casting inspection:

We can find out the problem of raw material, such as shoddy casting, unqualified wall thickness, chemical composition and so on, which ensure that you will not be cheated.

Machining Inspection:

On the one hand, we could ensure machining accuracy through this process. On the other hand, we could find out machining mistakes as early as possible, to win more time for repairing and remaking

Final Inspection:

Final inspection activities include document and QC record review, visual examination, dimension check, pressure test, painting and packing check. You don’t need to come and inspect in person and all the documents could be provided as proof.

Keywords of ASTM A105 Floating Ball Valve, 2PC, DN50, PN160, API 6D

A105 ball valves

Ball valves with actuator

Lens gasket ball valves