Key Specifications / Features

Model No.: Hits: 367

Detail Information

Quick Detail:

| Type | Ball Valve. |

| Size | 2 Inch. |

| Pressure | PN16, Class 150 LB. |

| Construction | Floating Type, Firesafe Design, Antistatic System, Anti-Blowout Stem. |

| Connection | NPT. |

| Operation Mode | Lever. |

| Body Material | ASTM A182 F304. |

| Trim Material | F304 Ball and Stem, PEEK Seat. |

| Design & Manufacture | DIN 3357. |

| Fire Safe Test | API 607. |

| Screwed End | ANSI B1.20.1. |

| Inspection | API 598. |

| Temperature Range | -29℃~+200℃. |

| Medium | Oil, Water, Gas. |

Features:

FIRE SAFE DESIGN: Metal seat design provides a fire-safe shut off per API 607. Additionally, graphite body seals and flexible graphite packing prevents leakage through the body joints and stuffing box, respectively.

ANTI-STATIC DEVICES: Standard anti-static devices ensure electrical continuity between the ball, stem, and body, eliminating the possibility of sparks within the valve created by static electrical charges.

BLOWOUT-PROOF STEM DESIGN: Valves are designed with stem, body connection preventing stem blowout under line pressure.

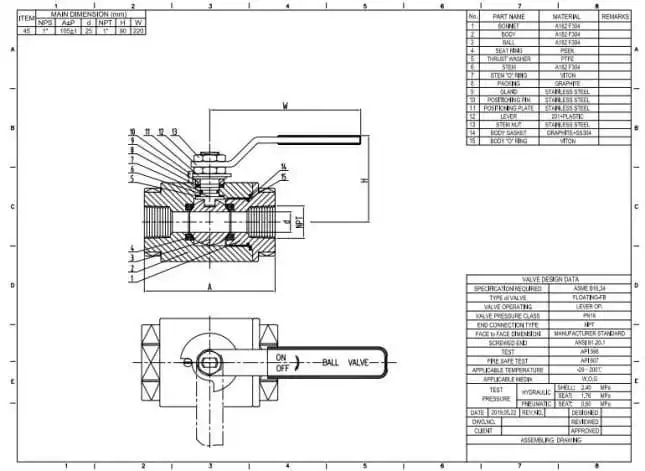

Technical Drawing

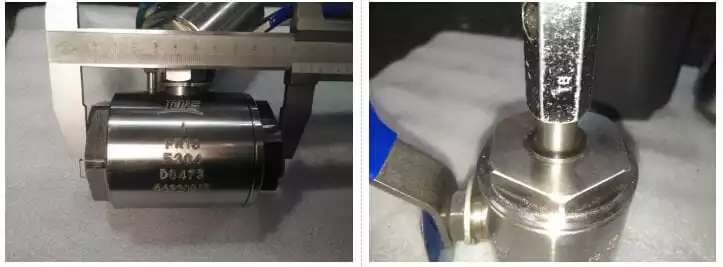

Dimension Check

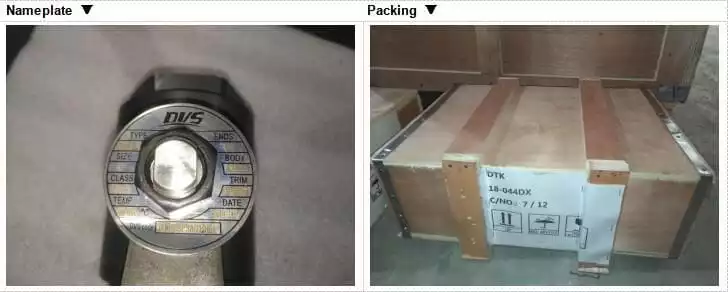

Nameplate & Packing

Dervos Packaging

Good packing means good first impression. Just imagine how do you feel differently when seeing two boxes below? And you will know the reason why in Dervos we value packaging so much.

In Dervos, we make sure-

Every valve is clean and dry. What do we do?

-Clean the valve before packing

-Add anti-rust oil

-Add flange cover

No damage to valves in delivery. How do we achieve this?

-Fix the valve with iron wire

-Separate the valve with soft material

-Layer the valve with plywood

Strong box and clear shipping mark