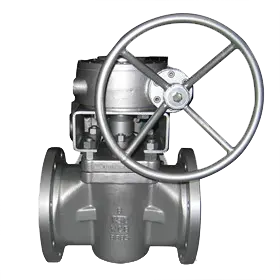

The Sleeve Type Plug Valve is a valve specifically designed for precise control of fluid flow. Due to its unique design and functionality, it performs exceptionally well in many industrial applications. However, like any valve, it has its own set of advantages and disadvantages.

One of the major advantages of the Sleeve-Type

Plug Valve is its excellent sealing performance. The sealing design between the plug and the sleeve effectively prevents medium leakage, ensuring the safety and reliability of the system.

The design of this valve allows for precise control of fluid flow and pressure. By adjusting the angle of the plug, fine regulation of the fluid flow can be achieved, meeting the requirements of various operating conditions.

The sleeve-type plug valve, due to its unique structure, can handle fluids containing solid particles and has strong wear resistance. This makes it suitable for a variety of complex operating environments.

Many sleeve-type plug valves are made from corrosion-resistant and high-temperature materials, enabling them to operate reliably in chemical, petroleum, and other corrosive or high-temperature media.

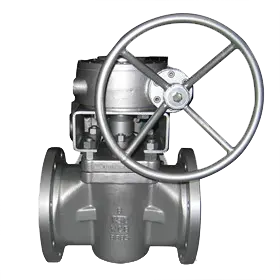

5. Easy Maintenance

Due to its structural design, the sleeve-type plug valve is relatively easy to maintain. Typically, regular inspection and replacement of seals or lubricants are sufficient to keep the valve operating smoothly.

Due to its precise fluid control capabilities and excellent sealing performance, the sleeve-type plug valve is generally considered a highly reliable type of valve, capable of operating consistently and stably even in harsh environments.

Due to the higher design and material costs associated with sleeve-type plug valves, their initial purchase price is typically more expensive compared to other types of valves. This can put pressure on projects with limited budgets.

The structural design of sleeve-type plug valves makes them relatively large, occupying more installation space. In situations with limited space, their size may become an issue.

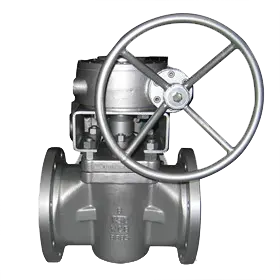

While the maintenance of sleeve-type plug valves is relatively simple, their operation and adjustment may require specialized knowledge. This complexity can increase, especially in applications requiring precise control.

Although the valve exhibits strong wear resistance, prolonged use may still lead to wear on the contact surfaces between the plug and the sleeve. Regular inspection and replacement of components are necessary to prevent performance degradation.

Although sleeve-type plug valves can handle a variety of media, their compatibility may not be as high as that of other specialized valves when dealing with certain highly corrosive or unique media.

6. Maintenance Frequency Requirements

Although the maintenance process is relatively simple, frequent maintenance and inspection are still necessary to ensure the long-term proper functioning of sleeve-type plug valves. Failure to perform timely maintenance may affect their performance and lifespan.