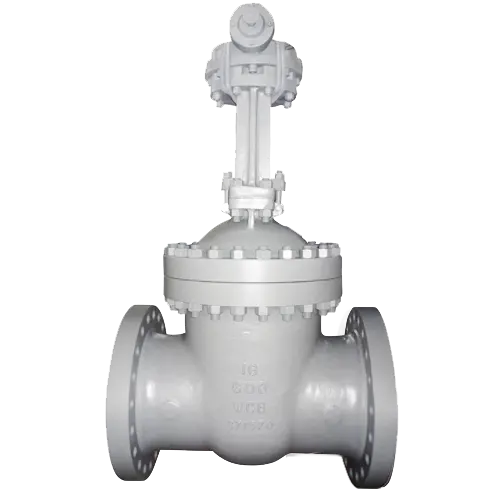

Gate valves are crucial components in various industrial applications, primarily designed for on-off control of fluid flow. Their construction allows for rapid full opening or full closure, making them ideal for situations requiring complete flow shutoff. Commonly utilized in industries such as oil, gas, and water treatment, gate valves play a significant role in ensuring operational efficiency and safety. However, despite their advantages, gate valves are less effective when it comes to flow regulation, presenting challenges that can lead to operational inefficiencies.

1. Design Purpose and Limitations

Gate valves are engineered with a straightforward mechanism that raises or lowers the valve disc to control the passage of fluids. This design enables quick access to full flow or complete shutoff, which is essential in many critical processes. However, their inherent design is not suited for applications that require nuanced flow regulation. In scenarios where precise control of fluid dynamics is essential, gate valves can be problematic. When only partially opened, they may cause unstable fluid flow, leading to unpredictable pressure variations and inefficient operation. This limitation is particularly concerning in systems where consistent flow rates are crucial, such as in chemical processing and water treatment facilities.

2. Insufficient Control Precision

The operational mechanism of gate valves can contribute to control precision issues. Unlike globe valves, which feature a more complex flow path design, gate valves lack the ability to finely adjust the flow rate. Globe valves provide smoother flow transitions and better regulation capabilities, making them the preferred choice in applications where precision is paramount. The limitations of gate valves become more pronounced in situations involving varying fluid characteristics or complex process requirements. For instance, industries that demand accurate dosing or mixing often find that gate valves fall short of providing the necessary control, necessitating a reevaluation of valve choices.

3. Risks and Damage

Using gate valves in flow control applications can lead to significant wear and potential damage over time. When a gate valve is partially open, the resulting turbulence can accelerate wear on the valve seat, increasing the likelihood of failure—especially in high-pressure or high-temperature environments. This risk is particularly acute in critical applications such as oil and gas pipelines, where the integrity of valves directly impacts safety and operational costs. Preventative maintenance becomes essential, but frequent replacements due to premature failure can lead to increased downtime and operational inefficiencies.

4. Vibration and Noise Concerns

Another consequence of using partially open gate valves is the increased vibration and noise generated within the pipeline system. Fluid turbulence, a byproduct of imprecise flow control, can lead to significant vibrations, potentially causing structural damage to piping systems over time. Moreover, the increased noise levels can create uncomfortable working conditions, particularly in sectors like water treatment and food processing. In these industries, excessive noise not only poses a risk to employee health but can also violate regulatory standards regarding workplace safety and environmental impact.

5. Exploring Better Alternatives

Given the limitations of gate valves for flow control applications, industries are increasingly turning to more suitable valve types. Globe valves are particularly popular in the chemical and petroleum sectors due to their superior design that allows for precise flow regulation. Their ability to handle varying pressures and flow rates makes them invaluable in applications requiring accuracy.

Butterfly valves also present a compelling alternative, known for their rapid opening and closing capabilities. These valves are frequently employed in HVAC systems, wastewater treatment facilities, and other applications where efficient regulation of air and liquid flow is paramount. Their lightweight design and quick operation enhance system responsiveness, making them ideal for dynamic environments.

Additionally, ball valves are renowned for their low fluid resistance and excellent sealing properties, making them particularly well-suited for high-pressure and high-temperature applications. Their robust construction and reliability make them a go-to option in a range of industries, ensuring that fluid control remains effective even under challenging conditions.

Conclusion

While gate valves serve essential functions in various industrial applications, their limitations in flow regulation and control precision cannot be overlooked. As industries continue to evolve and demand more from their fluid control systems, exploring alternative valve types such as globe, butterfly, and ball valves will be crucial. By adopting these more suitable solutions, companies can enhance operational efficiency, reduce maintenance costs, and ensure a safer working environment.