Cavitation In Control Valves - E.G. Butterfly Valve

When the

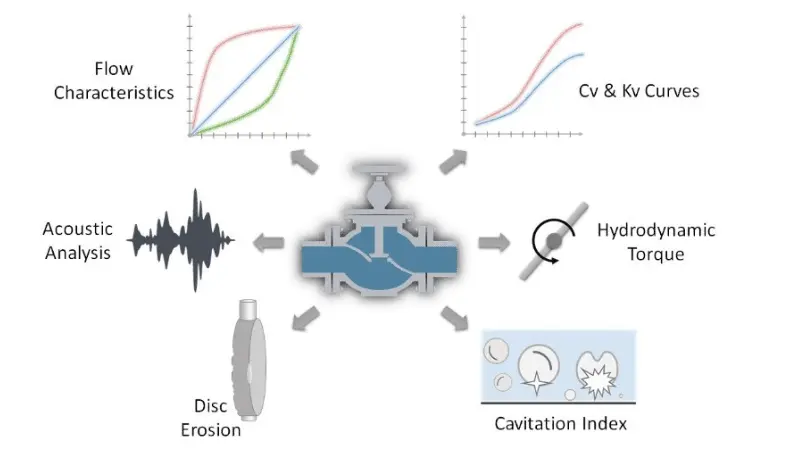

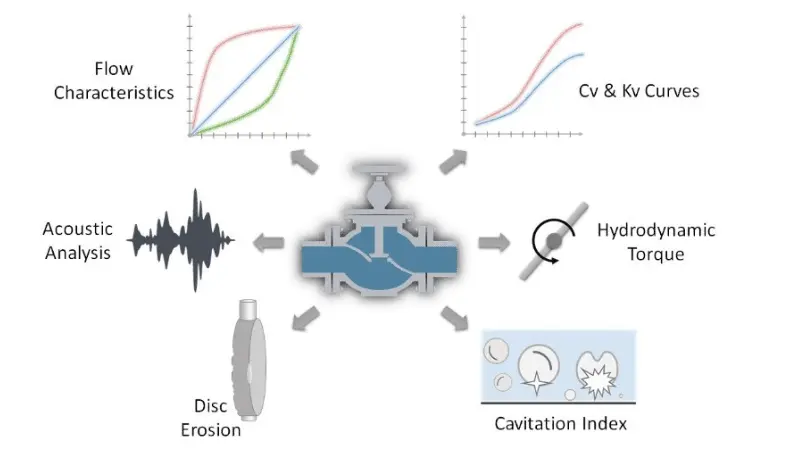

control valves are used in liquid service, they may experience localized cavitation. Cavitation consists of the formation of liquid vapor cavities when the local static pressure drops to the liquid vapor pressure. The vapor cavity collapses once Localized damage to the valve and surrounding area occurs. Valve designs that reduce cavitation are based on empirical evidence and accumulated experience, but there are still considerable cavitation problems in industry. Effective control of cavitation in industrial processes has evolved considerably over the last several decades, but nevertheless remains an area of challenging and focused study. A major impediment to understanding valve cavitation is the limited visual access a researcher has to the flow field within the valve. Typically the intensity and location of cavitation effects must be inferred from other measurements such as valve noise, vibration, or damage to the valve assembly.

Butterfly valves may be used to control flow in pipes if they are throttled in angles where the valve works stable without noise or vibration, i.e., cavitation free. Acoustic signatures have been used to identify cavitation from butterfly valves, but the understanding of the cavitation field could be improved through visualization.