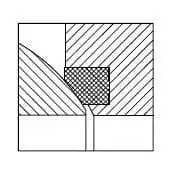

The ball of the ball valve is floating. Under the action of the medium pressure, the ball can generate a certain displacement and press against the sealing surface at the outlet end to ensure the sealing of the outlet end.

The floating ball valve has a simple structure and good sealing performance, but the load of the ball subjected to the working medium is all transmitted to the outlet sealing ring, so it is necessary to consider whether the sealing ring material can withstand the working load of the spherical medium, and when being subjected to a high-pressure impact, the sphere may be offset. This structure is generally used for medium and low-pressure ball valves.

2. Trunnion mounted ball valve

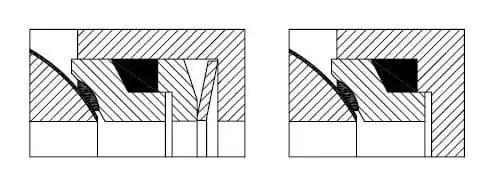

The ball of this ball valve is fixed and does not move after being pressed. The Trunnion mounted ball valve has a floating valve seat. Under medium pressure, the valve seat moves, so that the sealing ring is pressed against the ball to ensure the seal. It is usually mounted on the upper and lower shafts of the ball, the operating torque is small, suitable for high pressure and large diameter valves.

3. Soft seal ball valve

The seat material is generally non-metallic, such as PTFE, RPTFE, nylon, PEEK, PPL, etc.

4. Hard seal ball valve

The sealing surfaces of the ball and the valve seat are usually subjected to hardening treatment methods such as carburizing, nitriding, spraying, surfacing and the like.

5. Top-mounted ball valve

The structural feature of such a ball valve is that the valve body is made in one piece. A valve cover, a ball body, and a valve seat are mounted on the upper portion of the valve body. The advantage of the top-mounted ball valve is that it is not necessary to remove the ball valve from the pipeline when servicing and replacing the valve seat. Only open the valve cover and lift the ball.

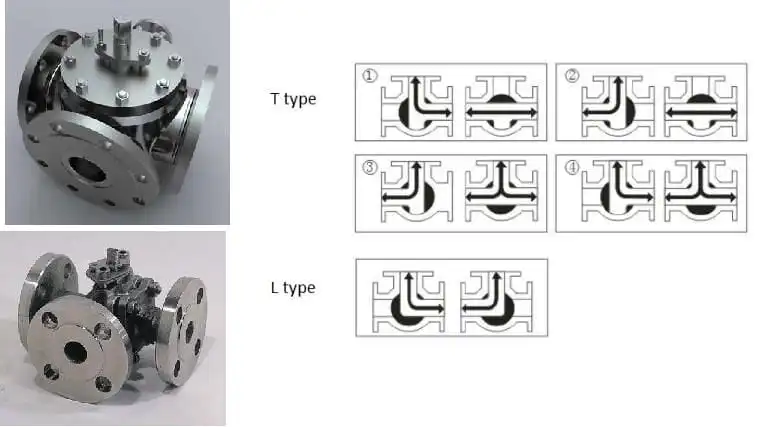

6.Three-way ball valve

Three-way ball valves are available in T and L versions.

The T-type enables three orthogonal pipes to contact with each other and cut off the third channel to function as a split and merge.

The L-type three-way ball valve type can only connect two pipes that are orthogonal to each other, and cannot keep the third pipe connected to each other at the same time, only to distribute.