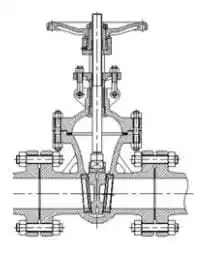

1. Flange connection: Flange connections are the most common form of connection between valves and piping or equipment. It refers to the detachable connection of the flange, the gasket and the bolt as a set of combined sealing structures. Flange connection can be applied to valves of various nominal sizes and nominal pressures, but there are certain restrictions on the use temperature. In high temperature conditions, the flanges will be prone to creep and cause leakage. Under normal circumstances flange connection is recommended for use at temperatures below 350 °C.

According to the shape of the joint surface, it can be divided into the following types: FF, RF, RTJ.

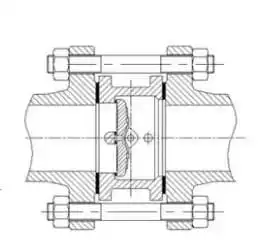

2.Wafer connection: A connection form in which the valve and the two pipes are directly clamped together by bolts.

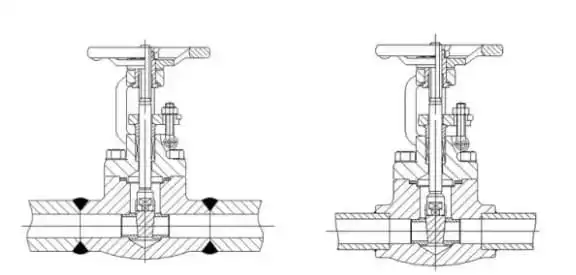

3.The welded connection refers to a connection form in which the valve body has a welding groove and is connected to the piping system by welding. API600, ASME B 16.34 and other standards have specified welding bevels. The welded connection between the valve and the pipe is divided into a butt weld connection (BW) and a socket weld connection (SW). Socket weld end shall comply with the provisions of JB/T 1751. Butt weld connection (BW) can be applied to various sizes, various pressures and high temperature conditions. Socket weld connection (SW) is generally suitable for valves of ≤ DN50.

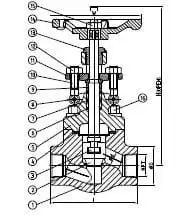

4.NPT connection: This is a simple connection method often used for small valves.

5.Sleeve connection

6.Clamp connection

7.Internal self-tightening connection