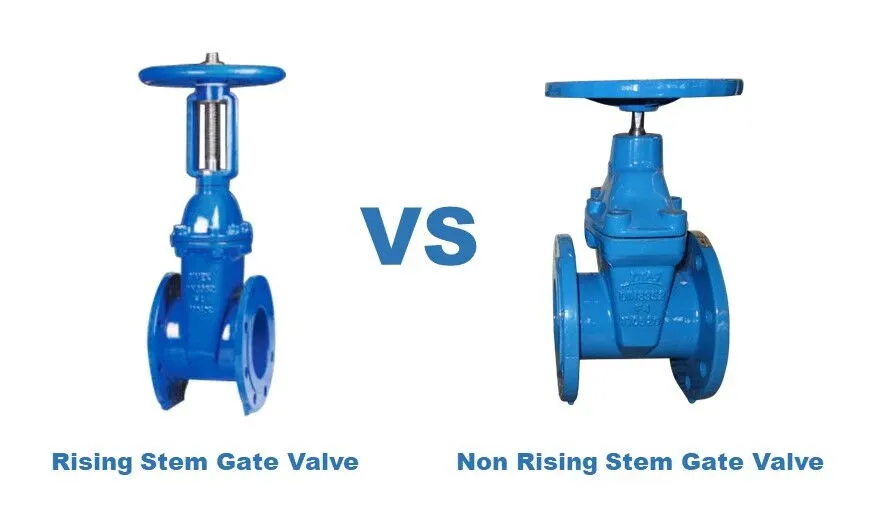

In the valve industry, gate valves, as a common type of fluid control device, are widely used in various pipeline systems. Gate valves can be classified into rising stem gate valves and non-rising stem gate valves based on the structure of the valve stem. There are significant differences in structure between the two, which in turn affect their scope of application and operational performance.

Structure of Rising Stem Gate Valve

Exposed Stem

In the rising stem gate valve, the stem ascends or descends during the opening and closing process, exposed externally as it moves with the rotation of the handwheel. The position of the stem's ascent or descent allows for a visual determination of the valve's open or closed state.

Operating Mechanism

The operating mechanism of the rising stem gate valve is typically located externally on the valve body, with the handwheel connected to the stem through a nut. As the handwheel rotates, the nut drives the vertical movement of the stem, thereby lifting or lowering the gate to open or close the valve.

Structural Characteristics

Due to the exposed stem, the rising stem gate valve exhibits a relatively simple structure, facilitating lubrication and maintenance. Additionally, the rising stem design reduces contact between the stem and the medium, thus extending the valve's service life.

Structure of Non-Rising Stem Gate Valve

Stem Concealed Design

In the rising stem gate valve, the stem does not ascend or descend during the opening and closing process. Instead, it achieves the elevation of the gate through the rotation of the stem nut. The stem remains at a fixed length, concealed within the valve body.

Operating Mechanism

The handwheel of the rising stem gate valve directly drives the elevation of the gate through the rotation of the stem nut. As the stem does not ascend or descend, the position of the handwheel remains unchanged regardless of the valve's open or closed state, necessitating alternative means to determine the valve's status.

Structural Characteristics

The concealed stem design enhances the overall compactness of the valve, making it suitable for installations with limited space. Additionally, as the stem remains concealed, it reduces the susceptibility of the stem to corrosion from external environmental factors.

Comparison of advantages and disadvantages

Rising stem gate valve

Advantages: Provides a visual indication of the valve's open/close status, facilitating operation and maintenance. The exposed stem allows for easy lubrication and corrosion prevention. It features a simple structure, making it convenient for repairs.

Disadvantages: The exposed stem is susceptible to external environmental influences, posing potential safety hazards. It requires a larger installation space and is not suitable for confined spaces.

Non-rising stem gate valve

Advantages:

The stem is concealed within the valve body, providing a compact structure suitable for installations with limited space. With the stem not exposed, it reduces the impact of external environmental corrosion, thus extending the service life.

Disadvantages:

The open/close status of the valve is not visually apparent and requires additional indication devices. The stem comes into direct contact with the medium, making it susceptible to corrosion, necessitating special material protection.

Applicable scope

Rising stem gate valve:

Suitable for applications requiring clear indication of valve open/close status, such as industrial pipeline systems, municipal engineering, water treatment, etc.

Non-rising stem gate valve:

Suitable for installations with limited space or harsh environments, such as underground pipeline systems, ships, petrochemicals, etc.

Summary

The significant structural differences between rising stem gate valves and non-rising stem gate valves lead to their respective emphasis in practical applications. The selection of the appropriate gate valve type needs to be comprehensively considered based on specific operating environments and working conditions. Rising stem gate valves, with their intuitive operation and ease of maintenance, are suitable for occasions requiring frequent operation and visual judgment. On the other hand, non-rising stem gate valves, with their compact structure and strong environmental adaptability, perform well in situations with limited space or harsh environmental conditions.

By understanding the structural differences and pros and cons between rising stem gate valves and non-rising stem gate valves, users can more accurately select and utilize valves, thus enhancing the operational efficiency and safety of pipeline systems.