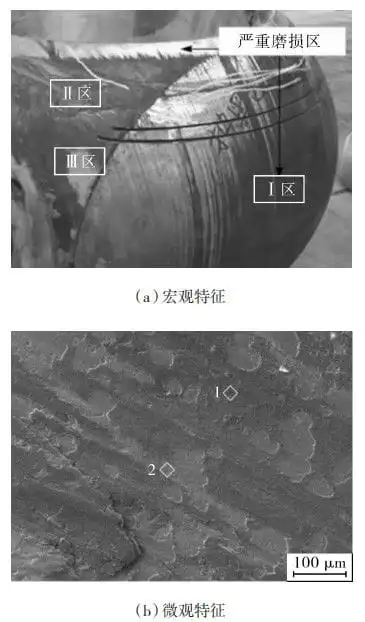

Failures caused by abrasive wear are that the solid impurities such as particles in the valve scour the surface of the valve parts in the flowing process, resulting in damage and failures. Xiangqing Wu and other analyzed the characteristics of failures caused by abrasive wear of spherical spools. Under the macroscopic state, there were bright white areas on the surface of the parts. The gully was parallel and had approximately the same spacing. The lamellar morphology and surface delamination left by pressing are shown in Figure 1.

Figure 1 Characteristics of failures caused by abrasive wear

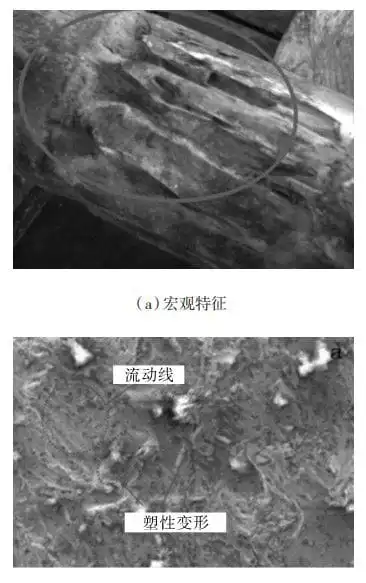

Failures caused by corrosion wear refer to the failure in which the flow channel structure is damaged by corrosion wear and solid particle impurities when the flow medium in the valve is corrosive. Yaqing Wang and others analyzed the macroscopic characteristics of corrosion and wear on the surface of the gate valve stem, and found that grooves shaped like a gully appeared on the surface, as shown in Figure 2(a). There is no corrosion product on the surface of the parts that suffer from corrosion wear, which is different from failures caused by corrosion, because the corrosion product is taken away in the flow and flushing process of the fluid. Guofu Ou and others observed the microscopic characteristics of the corrosion and wear of the valve core of the high-pressure coal water slurry valve, and found that there were partial plastic deformation areas, extensive cutting and sliding areas on the wear surface, as shown in Figure 2(b).

Figure 2 Characteristics of failures caused by corrosion wear

At present, the differences between the macroscopic characteristics of failures caused by abrasive wear and corrosion wear are not clear, both of which are represented by grooves caused by wear. In the future, in-depth comparison and analysis of the differences in the macroscopic and microscopic dual characteristics of different failures caused by wear should be carried out, and an accurate identification method should be obtained.

Reasons for failures caused by wear

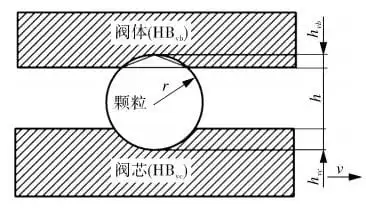

As shown in Figure 3, the process of failures caused by abrasive wear is that the solid particles contained in the fluid impact cut and squeeze the surface of the valve parts, causing them to have plastic deformation. In the fluid flow process, all plastically deformed materials will be removed, and a small portion will accumulate on both sides of the trench.

Figure 3 the process of failures caused by abrasive wear

Compared with failures caused by the abrasive wear, failures caused by corrosion wear have the effect of the corrosive medium in addition to the abrasive friction effect. Moses and others analyzed the reasons for the failure caused by the wear of the ball valve body, and found that the solid particles contained in the fluid scratched the surface of the valve body in the flowing process. At the same time, the chloride ions contained in the fluid had a chemical reaction with the surface of the valve body. The generated corrosion products were separated from the surface of the valve body and flowed with the fluid, leaving a corrosion area on the surface of the valve body.

Table 4 lists the research on the causes of failures caused by wear by domestic and foreign scholars. The influencing factors that cause wear include environments, structures, loads, processes and materials.

Table 4 Analysis of cases of failures caused by wear

| Researchers | Types of failures | Locations of failures | Causes of failures |

| Moses | Failures caused by corrosion | Ball valve bodies | There is a chemical reaction between chloride ions and valve body surfaces and friction occurs between particles. |

| Fei Guo | Failures caused by corrosion wear | Valve internals | Corrosive media reduce mechanical properties. |

| Minghong Liu | Failures caused by abrasive wear | Valve spools and valve bodies | Fluids contain solid particle impurities. |

| Bin Li | Failures caused by abrasive wear | Globe valve heads | Improper quenching process control makes the hardness of the surface infiltration layer insufficient. |

Insufficient hardness for the material's surface is the main cause of failures caused by wear, because the process control is improper. Surface quenching is a process to improve the surface hardness and wear resistance of parts, but the quenching process needs to be strictly controlled. At present, the structural factors of failures caused by wear are for specific components. An in-depth analysis should be performed in the future. At the same time, advanced surface treatment will also be the focus of research in this field.