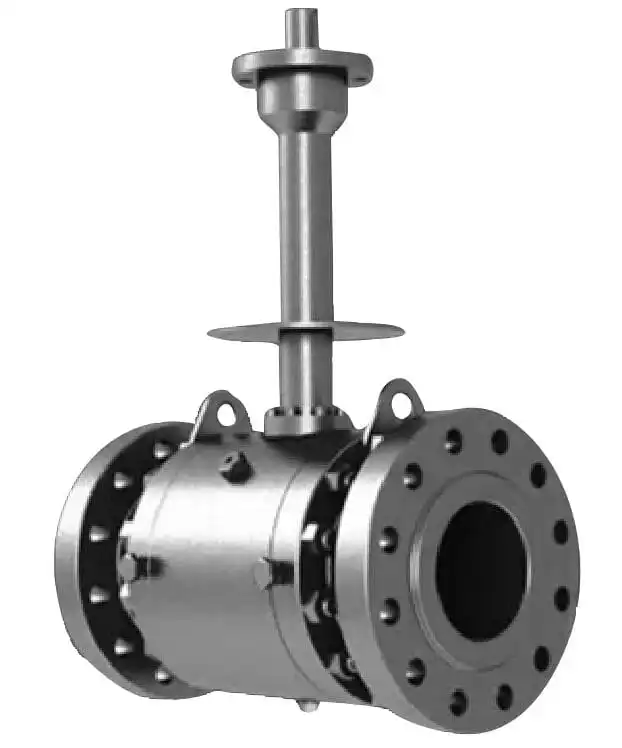

Descriptions of Ultra Low Temperature Ball Valves

The definition of low-temperature valves in the petrochemical industry is based on the design temperature of the transported medium. Valves used at medium temperatures below -40℃ are generally called low-temperature valves, while valves used at medium temperatures below -101℃ are called ultra-low-temperature valves.

Ultra-low temperature ball valves are mainly used in equipment for liquefied natural gas, liquefied petroleum gas, and air separation industries. The output liquid low-temperature media includes liquid oxygen, liquid hydrogen, liquefied natural gas and liquefied petroleum products.

Ultra-low temperature ball valves have special requirements for the valve sealing structure when applied to flammable, explosive, and easily vaporized media. This is because the ball valve generally has a closed valve chamber in its structure, and when the medium vaporizes, the volume expands sharply. Therefore, the design of the sealing structure of the ball valve must consider the pressure relief for the closed valve chamber. Ball valves can be classified into floating balls and fixed balls according to their structure. There are obvious differences in pressure relief design due to the different valve sealing principles of the two types of ultra-low temperature ball valves.

Structural Design Features

Ultra-low temperature ball valves have significant differences in structural design from other types of valves due to the special nature of their use environment and medium.

1. Extended valve cover design and drip plate design

2. Fireproof and anti-static design

3. Valve cavity pressure relief design and valve sealing ring design

Installation precautions

1. Valve stem installation angle: The valve stem of the ultra-low temperature ball valve cannot be installed horizontally.

2. Pressure relief direction: The pressure relief of the ultra-low temperature ball valve is generally in the upstream direction.

3. Thorough drying of the valve: The ultra-low temperature ball valve is used under low temperatures, and if there is water accumulation inside the valve, the water will freeze and expand at low temperatures, creating pressure on the internal components of the valve, leading to poor sealing or even structural damage. After water pressure testing, ultra-low temperature valves must undergo strict drying before leaving the factory.

As the application of liquefied natural gas becomes increasingly widespread, the demand for safety in natural gas pipeline systems will continue to rise, leading to even higher requirements for the structural design of ultra-low temperature ball valves. Special attention should be paid to the design, installation, and operation of pipeline systems and valves to ensure safe operation of the system and reduce environmental pollution, hazards, and personal injury.