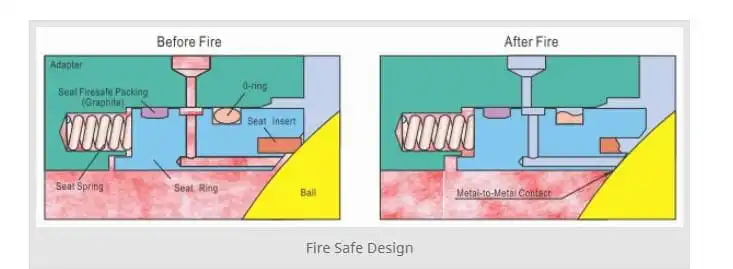

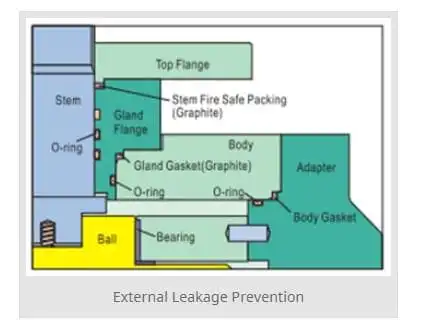

We will talk about the ball valve fire safe design from perspectives of internal leakage prevention and external leakage prevention.

For internal leakage prevention, the upstream pressure will push the ball to downstream metal seat to cut off medium and prevent the internal leakage when the soft seat is destroyed because of the fire. In addition, a fireproof packing of graphite at the metal seat ring can also prevent internal leakage.

For external leakage prevention, there will be two layers of sealing at all the possible external leakage points between stem & gland flange, gland flange & body, and body & adapter, one is O-ring, and the other is graphite gasket. The secondary graphite gasket will prevent external leakage when the O-ring sealing is burnt.

Generally speaking, the fire testing of ball valve is carried out as per API 6FA, API 607, ISO 10497 or BS 6755 Part II.

Next: What is a Plug Valve?

Previous: Classification of ball valves