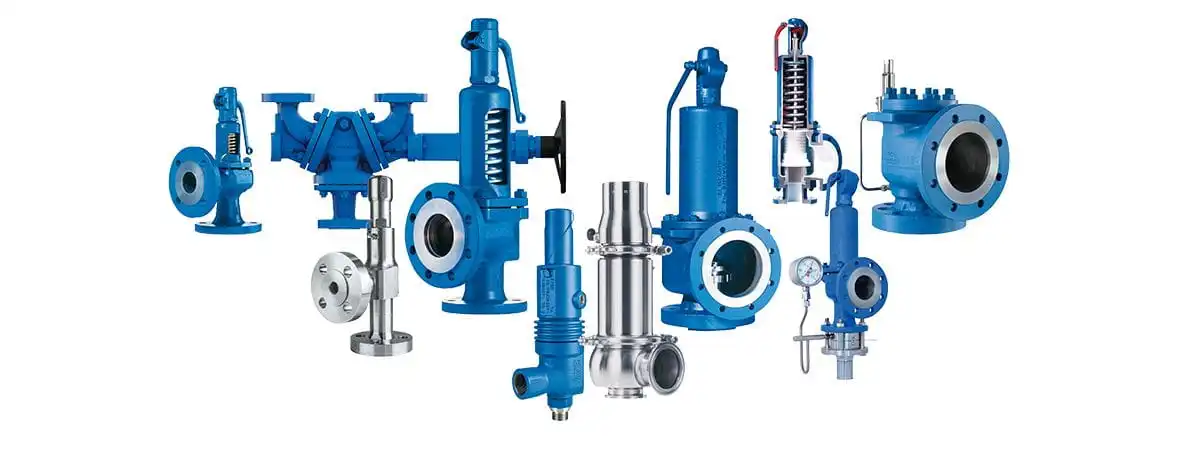

Common safety valves generally have the following types:

1. According to the overall structure and the loading structure, it can be divided into three types: heavy hammer lever type safety valve, spring type safety valve and control type.

2. According to the ratio of the valve opening height to the valve circulation diameter, it can be divided into a micro-open type and a full-open type safety valve.

3. According to the way of safety valve gas discharge, it can be divided into three types: fully enclosed, semi-closed and open.

The selection of a suitable safety valve should be considered from the following aspects:

1. The structural form depends mainly on the process conditions of the equipment as well as the working medium and characteristics. Generally, the spring type safety valve is often used when the amount of boiler and pressure vessel is not large. Otherwise, it is better to select the full-open safety valve.

2. If the medium is toxic, flammable and explosive, the closed safety valve should be selected.

3. Each safety valve has its own working pressure range. When selecting, it should be selected according to actual needs.

4. The discharge of the selected safety valve must be greater than the discharge amount of the equipment, so as to ensure that part of the medium is removed and the pressure is prevented from rising.