Structure design of full welded ball valves

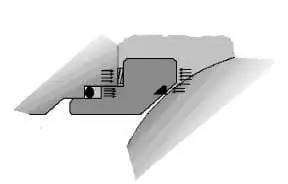

The structure of the full welded ball valve described herein is shown in the picture below. The biggest difference between this type of ball valve and the traditional three-way ball valve is that the way of full welded ball valve closing the ball is welded. Therefore, the inner and outer linings are important during the welding process. In addition, the installation of the ball valve on the pipeline is also by means of a welded connection.

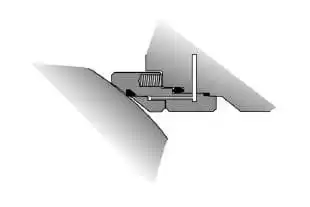

The seat sealing construction is generally double sealing (upstream and downstream double sealing). The valve seat inserts have excellent corrosion resistance, wear resistance and good elasticity, and high sealing performance. The structure of the valve seat is shown in the photo below.

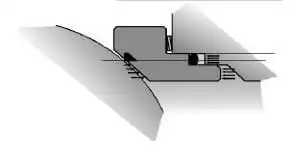

The principle of the valve seat double sealing construction is as follows

(1)Sealing principle of the upstream seat: Due to the upstream force, the seat is pressed by the ball to form a seal, as shown in Figure 3.

Sealing principle of the seat on the downstream side: The seat is sealed by the ball due to the pressure in the valve body, as shown in Figure 4.