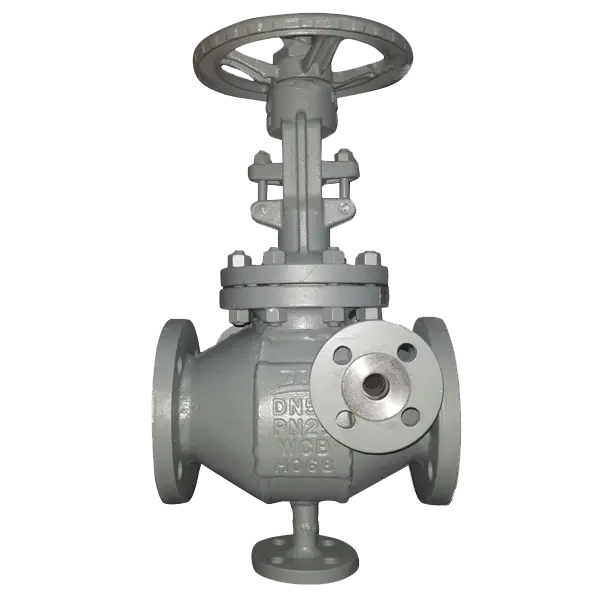

A heating jacket gate valve is a type of valve specifically designed to maintain the temperature of the fluid within a pipeline. Its design aims to prevent the fluid from solidifying or freezing in low-temperature environments by circulating a heating medium through the jacket.

The basic structure of a heating jacket

gate valve is similar to that of a standard gate valve, but its unique jacket design enables it to provide heating and insulation. The main components include:

Valve Body

The valve body is the main part of the valve, typically made from cast steel, stainless steel, or alloy steel, offering good strength and corrosion resistance.

The wedge, is a critical component for controlling fluid flow by moving up and down to open or close the valve. It is typically made from wear-resistant and corrosion-resistant materials to ensure long-term stability and performance.

The stem connects the gate to the actuator and transmits the operating torque to move the gate up and down. It is typically made of high-strength stainless steel, offering excellent corrosion resistance and mechanical properties.

The jacket is a distinctive feature of the heating jacket gate valve, encasing the exterior of the valve body. It allows for the circulation of heating media (such as steam or hot oil) to maintain the temperature of the valve body and the internal fluid through thermal conduction.

The actuator can be manual, electric, or pneumatic, and is used to operate the valve stem, thereby controlling the opening and closing of the wedge.

The sealing components include the seals between the valve body and the wedge, as well as the packing between the valve stem and the bonnet, ensuring that the valve remains leak-proof when closed.

The working principle of a heating jacket gate valve is to maintain the temperature of the valve and its internal fluid by circulating a heating medium within the jacket, preventing the medium from solidifying or freezing in low-temperature environments. The specific working process is as follows:

When the valve is in the open position, the gate (wedge) is lifted to the fully open position by the valve stem, allowing fluid to flow freely through the valve body with minimal resistance.

When the valve needs to be closed, the valve stem drives the gate (wedge) downward to the fully closed position. The gate seals tightly against the valve seat, cutting off the fluid flow and ensuring no leakage.

The heating medium (such as steam or hot oil) enters the jacket through the inlet and outlet pipes and circulates around the valve body. The heating medium maintains the temperature of the valve body and the internal fluid through thermal conduction, preventing the medium from solidifying or freezing and ensuring the normal operation of the valve.

In petrochemical production, many media tend to solidify or become viscous at ambient temperatures. Heating jacket gate valves can maintain the temperature of these media during flow, preventing blockages.

In pharmaceutical production, certain pharmaceutical liquids need to be transported and reacted at specific temperatures. Heating jacket gate valves provide stable temperature control, ensuring the quality and efficiency of the pharmaceutical production process.

In food processing, certain liquid ingredients tend to crystallize or solidify at low temperatures. Using heating jacket gate valves helps maintain the flowability of these ingredients, enhancing the continuity and efficiency of the production line.