The valve body is of low-alloy structural steel plate Q345C and 25 forged steel welded structure. The fracture surface of the valve body is a double I-beam composite frame structure. The fracture surface's inertia modulus is great; the size and height of the fracture surface are reasonably designed, and the effect of the material on the strength and stiffness of the valve body is maximized. The bearing seat is made of 25 forged steel and adopts a box-type structure to withstand the concentrated load from the valve shaft in the most dangerous working conditions. The valve body is provided with symmetrical support to transmit the vertical load to the concrete base. The stand foot adopts a reinforced structure to increase the rigidity of the valve. The bearing hole is in the form of a waist hole, which allows the butterfly valve to have a slight displacement relative to the base plate along the axis of the penstock. The valve has a large diameter and weighs 95t after assembly. The valve body is symmetrically provided with 4 reinforced lifting lugs to facilitate the lifting of the valve. The stress and displacement of the valve body under various working conditions are analyzed by FEA finite element analysis using Solidworks software.

2. Butterfly plates and valve shafts

The butterfly plate has a low-alloy structural steel plate made of Q345C, 25 forged steel group welding, double-eccentric double-plate flow type split-frame structure, and hydraulic self-closing. The middle rib is symmetrically distributed on the left and right, and the edges of all the flow surfaces are processed into a fishtail. The flow interference effect on the flow surface is small, and the resistance coefficient does not exceed 0.12 when the butterfly valve is fully opened. In the process of closing the valve, the water-facing area of the lower half of the two eccentric discs is larger than that of the upper half, which helps the valve to be closed. The stress and displacement of the butterfly plate under various working conditions are analyzed by Solidworks software.

The valve shaft is in the form of 2 half shafts. The valve shaft is made of alloy steel 40Cr by forging; the contact surface between the valve shaft and the bearing is surfaced with a stainless steel layer for fine machining. The butterfly plate and the valve shaft are connected by zero-clearance assembly of taper pins, and the end face of the pin and the butterfly plate is welded and fixed. This welding seam has passed the 100% PT test, which meets the requirements for sealing the welding seam.

3. The shaft bearing of the valve

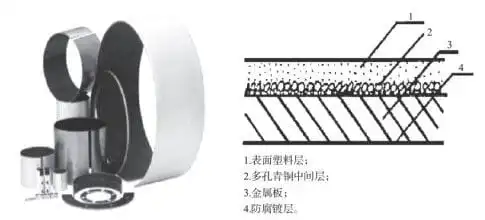

The valve shaft bearing is assembled in the shaft sleeve, adopting copper-backed PTFE composite materials, which has features of self-lubricating, maintenance-free, low friction coefficient (0.07 to 0.15), corrosion resistance, good wear resistance, good bearing capacity and long service life. The friction pair can form a stable PTFE solid lubricating film, which can satisfy oil-free lubrication and boundary lubrication. Hydraulic action will not cause the shaft to stick to the bearing. Therefore, this bearing structure makes it easy to replace the bearing and shaft seal without disassembling the valve body. The structure of copper-based self-lubricating bearing is shown in Figure 1.

Figure 1 Copper-based self-lubricating bearing

4. The sealing of the valve shaft

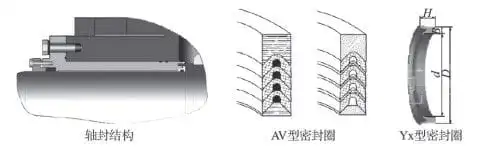

The sealing of the valve shaft is an orderly combination of Yx type and AV type sealing rings, and the sealing performance is automatically adjusted according to the size of the pressure (Figure 2). The Yx type seal is placed at the front end of the bearing, which effectively prevents sediment from entering the bearing and avoids the movement of the bearing from being blocked. The AV type combined seal (one PTFE support ring plus 2 NBR plus PTFE sealing ring plus 1 PTFE pressure ring) is a special structure with self-tightening and forced sealing functions. The packing can be supplemented and the sealing can be adjusted. It doesn't need to be maintained when it is put into use. There is no external leakage. After wear, a satisfactory sealing effect can be maintained continuously by adjusting the adjusting screw on the packing gland, and at the same time, it can meet the requirements of on-line maintenance of the shaft seal. This shaft seal structure is applied to large-diameter, high-pressure butterfly valves and blockages and leakages don't happen. It is a mature and advanced shaft seal scheme, especially suitable for this project.

Figure 2 The sealing of the valve shaft

5. The positioning structure of the shaft of the large valve

The valve shaft positioning adopts the patented technology of the large valve axial positioning structure. The butterfly plate and shaft use a bushing and a copper alloy plane thrust ring. The double-sided symmetrical top structure realizes the precise axial centering and positioning function of the butterfly plate, preventing any movement of the butterfly plate in the direction of the valve shaft and ensuring that the butterfly plate is in the middle. After the valve body is subjected to water pressure, improve the reliability of the sealing. In addition, the symmetrical structure on both sides to the top can effectively realize the synchronous and co-directional deformation (deformation coordination) control of the valve body, plate and shaft, and improve the assembly rigidity of the body, butterfly plate and shaft of the valve as a whole, which is beneficial to ensure the reliability of sealing and the realization of bidirectional sealing performance.

6. Waterstop working sealing

The water-stop working sealing pair is composed of a solid core T-shaped EPDM rubber ring with a special shape on the outer circle of the butterfly plate and a 06Cr19Ni10 stainless steel sealing seat inside the valve body. The rubber ring at the fully closed position of the valve has a great adjustable range for the compression amount and the sealing contact width, which can ensure zero leakage in the forward and reverse directions for specific sealing pressure under various working conditions. The T-shaped rubber ring is fixed in the positioning groove of the butterfly plate by stainless steel pressing screws and limit adjustment screws. The compression amount and contact width of the sealing ring are adjusted through the reserved gap between the pressing plate and the butterfly plate. Both the compression screw and the adjustment screw are provided with reliable anti-loosening measures.

7. Ultra-large torque intelligent integrated electric actuators

The electric actuator is mainly composed of a motor, a gearbox, a stroke control mechanism, an opening indicating mechanism, a manual electric switching mechanism, and a hand wheel. The electric actuator has its valve open, close and stop control buttons, on-site manual and remote automatic transfer switches, and a valve position sensor and torque sensor with 4 to 20mA analog output. The on-site control panel adopts digital liquid crystal display. The liquid crystal display has its power supply and has the function of normal display after power failure. The electric actuator adopts Rotork international well-known brand; the output torque is about 8.5×105N.m and the highest protection level is IP68 or above. It is completely waterproof and dustproof, and suitable for outdoor, humid and underwater working environments.