1. Structural features

1.1 Structural forms

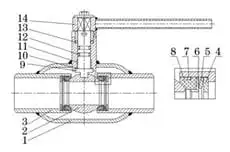

Steel pipe welded ball valves are divided into round floating welded ball valves, round trunnion welded ball valves, square floating welded ball valves, square trunnion welded ball valves, and spherical trunnion welded ball valves. The picture of a typical welded ball valve is shown in Figure 1.

Round floating welded ball valves are commonly used in DN15 to DN350. Round trunnion welded ball valves are often used in DN200 to DN600. Square floating welded ball valves are often used in DN50 to DN350. Square trunnion welded ball valves are often used in DN300 to DN1600. The sphere trunnion welded ball valve is often used in DN600 to DN1600.

1. Valve bodies 2. Spheres 3. Side tubes 4. Flat gaskets 5. Disc springs 6. Valve seat support rings 7. О rings 8. Valve seats 9. Stems 10. Thrust washers 11. Sliding bearing 12. O rings 13. O rings 14. Handles

Figure 1 Typical Welded Ball Valves

1.2 Valve bodies

The valve body with small and medium diameters is made of seamless steel pipes, and the valve body with large diameters is rolled by sheet metal. There are three types of welded ball valves, including round, square and sphere welded ball valves. The circular arc at both ends of the round valve body is formed by cold pressing of tooling. The arcs on both sides transition smoothly to reduce stress concentration, and the flange is omitted, which can reduce the weight of the valve and save the cost. The U-shaped welding groove is adopted between the valve body and the side body for the square valve body, which has good strength. Compared with the round body, it can withstand greater tensile stress, shear stress and combined stress of the pipeline. It is suitable for welded ball valves with large diameters. The spherical valve body's side body is formed by spherical forging, which has light weights, can reduce the material cost and the weight load of the pipeline. The welding seam in the middle of the valve body and the side body is far away from the valve seat. In the welding process, the heat effect and the deformation amount have a small impact on the surrounding of the valve seat.

The welding of the side body and the sleeve tube adopts butt welding; the welding seam is fully welded, and the stress concentration is reduced. The tensile strength is better than that of the fillet welding seam. The valve body shall be made of the steel pipe, rolled sheet or made by forging as a whole. The valve body's material should meet the requirements of GB/T713 or GB/T12228. When the valve body is made of seamless steel pipes, it should meet the requirements of GB/T8163 and GB/T14976. The welding coefficient of the valve body shall comply with the provisions of GB/T150.1, the welding structure design GB/T150.3, the welding process GB/T150.4, the processing 5.4 in GB50235-2010, and the minimum wall thickness of the valve body GB/T12224.

1.3 The sealing of the valve seat

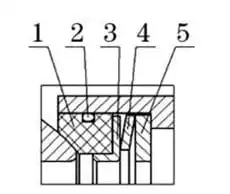

The floating ball valve seat (Figure 2) adopts an elastic valve seat sealing structure. The disc spring behind the valve seat can automatically compensate for the influence of temperature and pressure changes, natural wear and other conditions on the sealing performance of the ball; the valve seat’s sealing ring is pushed downstream by the sphere under the action of medium pressure due to the disc spring assembly, and the back of the valve seat is sealed with a radial О ring.

Figure 2 Floating Ball Valve Seats

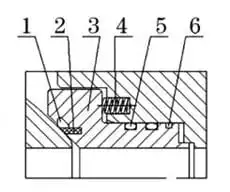

Figure 3 Trunnion ball valve seats

The trunnion ball valve seat adopts a piston type sealing structure (Figure 3), and a single or double piston valve seat structure can be selected. At present, most steel pipe welded trunnion ball valve seats are made of a polymer such as PTFE plus C and PPL. Valve seats made of such materials generally have problems such as poor sealing performance, poor deformation resilience, and great valve torque when they are put into use. Using triangular sealing can better avoid these problems. The spring pretightening specific pressure and sealing specific pressure of triangular sealing rings are about 1/3 smaller than those of PTFE plus C and PPL. Also, the opening and closing torque can be reduced by about 1/4.

The VITON AED fluororubber used for the triangular sealing ring has good elasticity compensation, which can reduce the requirement of the roundness of the sphere surface. Therefore, it not only has reliable and stable sealing performance, but also can reduce the processing cost of the sphere; if there is slight natural damage on the spherical surface when in use, the sealing performance can still be ensured. The triangular sealed seat can be used as the first seat structure for steel pipe welded ball valves with a long service life and no maintenance because of its excellent sealing performance.