In simple comparison, a 3 way valve has one more port than a 2 way valve. But why? A two way valve allows a fluid to enter the valve from one port, and exit through the other. Having a third port allows fluid an alternate path of travel, either when exiting or entering the valve. This permits fluid to either exit from more than one point, or enter the valve from more than one point.

What is a T-Port Valve?

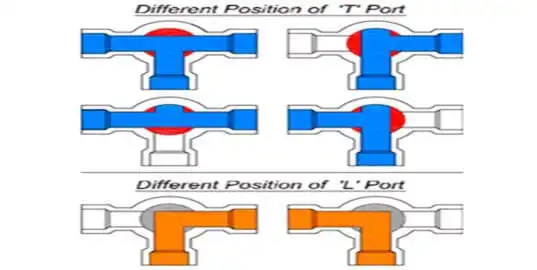

T-ports and L-ports, while similar, do different things. To accomplish this, the bore of the valve's ball is drilled in a particular shape. A "T" shape allows one action, while an "L" facilitates another. Both shapes provide options for diverting fluid flow from or to different sources, but each design offers unique functions. In the case of a ball drilled with a bore in the shape of a "T," fluid can be directed to more than one location simultaneously: when the ball is in the open position, fluid is allowed to pass through the valve at full pressure to point "A" while allowing fluid to travel to point "B" at a slightly lower pressure. In this way, a T-port 3-way valve is designed for directing fluid to multiple destinations.

What is an L-Port Valve?

An L-port valve, on the other hand, performs the opposite function, and directs fluid from multiple sources. For example, the use of an L-ported valve facilitates the ability to draw fluid from more than one source. A simple turn of the handle changes the position of the ball inside the valve and allows a change in the drawing source. So, when one tank is empty, fluid can be drawn from the next.