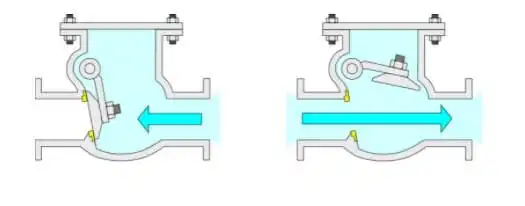

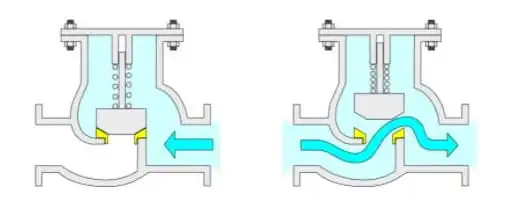

Different types of check valves use various accessories such as hinges, pistons, screens, and flaps. However, in simple terms, some sort of flap is used to allow flow in one direction and restrict flow in the other, hence they are also called "one-way" valves. How the flap moves along the flow is what makes most check valves different. It may be carried by a spring check valve, gravity swing check valve, or a combination of both.

Failed check valves can cause significant damage to the pipework. However, valves show signs of leakage and, if care is taken, can prevent damage over time.

Some of the first signs are excessive noise, vibration, and wear of internal valve components. Reverse flow and, in extreme cases, water hammers are also strong indications of valve failure. These challenges can be avoided at first, but may also require remedial action.

Important factors to consider in order to prevent valve failure are the appropriate flow diameter, reaction rate, and chemical compatibility. Installing filters where feasible will also help to prevent build-up and extend the life of the check valve.

Dervos offers quality various sorts of check valves, and our considerate services and professional help also set you free from worries about your purchases and products maintenance. Besides check valves, other common kinds like gate valves, ball valves, globe valves are also within our range. Give us a call or a mail today!