Introduction

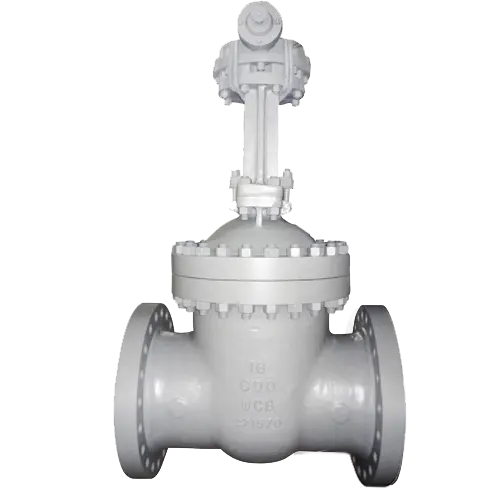

In large-scale engineering projects, gate valves are key equipment widely utilized. They play significant roles across various industrial sectors, owing to their unique design and functionality.First, let's understand the basic structure and working principle of gate valves. Gate valves are used to control the flow of fluids and primarily consist of a movable gate (usually rectangular or circular) and two well-sealing valve seats. When the gate is raised inside the valve body, fluid can flow freely; however, when the gate is lowered, the fluid passage is blocked. This simple yet effective design allows gate valves to control fluid flow quickly and reliably, hence their widespread use in large-scale engineering projects.

Reasons for Gate Valve Use in Large-Scale Projects

The widespread application of gate valves in large-scale engineering projects is mainly attributed to several reasons.High sealing performance

Gate valves adopt a bidirectional sealing design, with excellent sealing performance between the gate and the valve seats, effectively preventing fluid leakage. This high sealing performance makes gate valves particularly suitable for large-scale projects that require strict control of fluid flow, such as chemical plants and power plants."Quick Opening and Closing

Gate valves have a fast opening and closing speed, capable of completing the opening or closing of fluid passages in a short period. This is particularly important for certain engineering scenarios that require rapid response, such as emergency shutdowns or fluid pipeline switching.High Pressure Resistance and Corrosion Resistance

Gate valves are typically made of high-strength materials, capable of withstanding working conditions under high pressure environments. Additionally, the design of gate valves enables them to resist corrosion from various chemical substances, making them widely applied in industries such as chemical and petroleum.High Reliability

Due to the simple structure and reliable operation of gate valves, they have a low failure rate and can operate stably for long periods. This is particularly important for large-scale projects because valve failures could potentially lead to serious safety incidents or production interruptions.Suitable for High Flow Rates: The design of gate valves enables them to handle high flow rate conditions, meeting the fluid flow requirements in large-scale engineering projects.