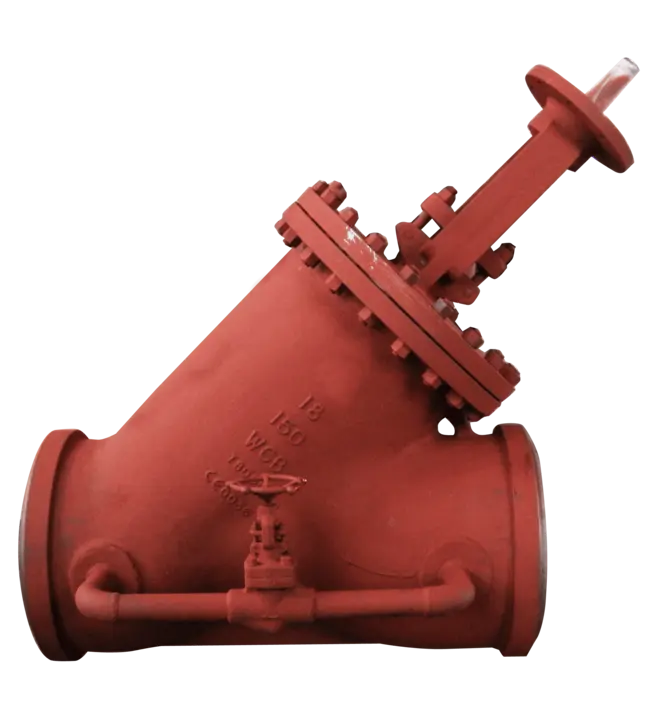

Structure of Y-type Globe Valve

The Y-type globe valve mainly consists of the following parts:

1. Valve Body

The valve body is the main part of the Y-type globe valve, typically made of materials such as cast iron, stainless steel, or brass. Inside the valve body, there is a Y-shaped structure that reduces fluid resistance.2. Bonnet

The bonnet is fixed on the valve body, providing sealing and supporting the valve stem.3. Valve Stem

The valve stem connects through the bonnet to the valve body and is operated for opening and closing by rotating a handwheel or actuator.4. Disc

The disc is connected at the lower end of the valve stem. Movement of the valve stem up and down opens or closes the disc, thus controlling fluid flow.5. Seat

The seat is fixed inside the valve body and forms a sealing surface with the disc to prevent fluid leakage.Working Principle of Y-type Globe Valve

The operating principle of the Y-type globe valve is relatively simple. It mainly controls the opening and closing of the valve disc by the up and down movement of the valve stem, thereby regulating and cutting off the flow of fluid. The specific process is as follows:

1. Valve Opening

When rotating the handwheel or operating the actuator, the stem moves upward, lifting the valve disc away from the seat. As the valve disc gradually rises, the fluid passage opens, allowing the fluid to flow smoothly. Due to the Y-type structure design, there is less resistance for the fluid passing through the valve, resulting in smoother flow.2. Valve Closing

When reversing the rotation of the handwheel or actuator, the stem moves downward, causing the valve disc to approach the seat. When the valve disc tightly contacts the seat, it forms a seal, completely blocking the fluid passage and stopping the flow. The design of the sealing surfaces between the valve disc and seat ensures excellent sealing performance, preventing fluid leakage.Advantages of Y-type Globe Valves

1. Low fluid resistance

The Y-type structure design reduces resistance as fluid passes through the valve, allowing smoother flow and lowering energy consumption.2. Excellent sealing performance

The sealing surfaces of the disc and seat are designed for superior sealing, making it suitable for applications with high sealing requirements.3. Simple structure

The Y-type globe valve has a simple structure with fewer components, making it easy to manufacture, install, and maintain.4. Convenient operation

The valve can be easily opened and closed by rotating the handwheel or using an actuator, providing flexible and convenient operation.Conclusion

The Y-type globe valve, named for its distinctive Y-shaped design, is a versatile industrial valve used for regulating and shutting off fluid flow. Its key components include a valve body, bonnet, valve stem, disc, and seat, each contributing to its efficient operation. The valve operates by the up-and-down movement of the valve stem, which opens and closes the disc to control fluid flow. The Y-shaped structure minimizes fluid resistance, allowing for smoother flow and reduced energy consumption.

Advantages of the Y-type globe valve include low fluid resistance, excellent sealing performance, a simple structure, and convenient operation. The robust sealing surfaces between the disc and seat ensure superior sealing, making it suitable for applications with high sealing requirements. Its straightforward design with fewer components facilitates easy manufacturing, installation, and maintenance. The Y-type globe valve is a reliable and efficient choice for various industrial applications.