Key Specifications / Features

Model No.: Hits: 0

Quick Detail

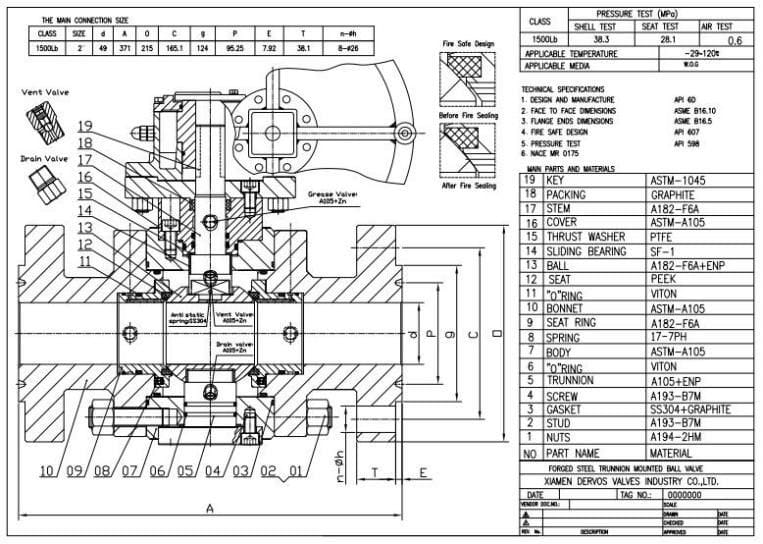

Type: Ball Valve

Size: 2 Inch

Pressure: Class 1500 LB

Construction: Trunnion-mounted, c, Full Bore

Connection: RTJ

Operation: Gear Operated

Body Material: ASTM A105

Design & Manufacture: API 6D

Face to Face: ASME B16.10

End Connection: ASME B16.5

Test & Inspection Code: API 598

Fire Safe: API 607

Temperature Range: -29℃ - 120℃

Medium: Water, Oil and Gas

Product Range

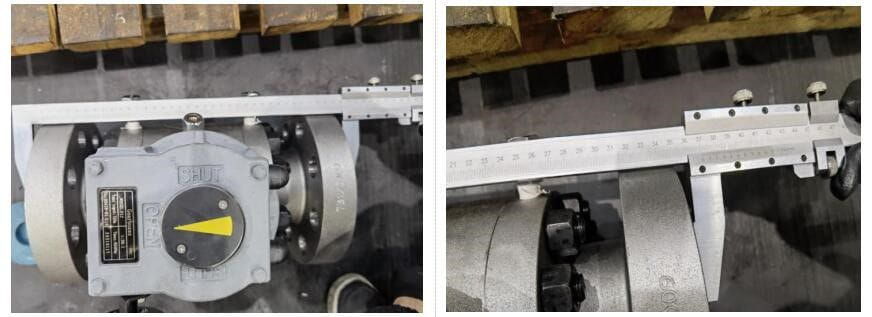

Dimension Check

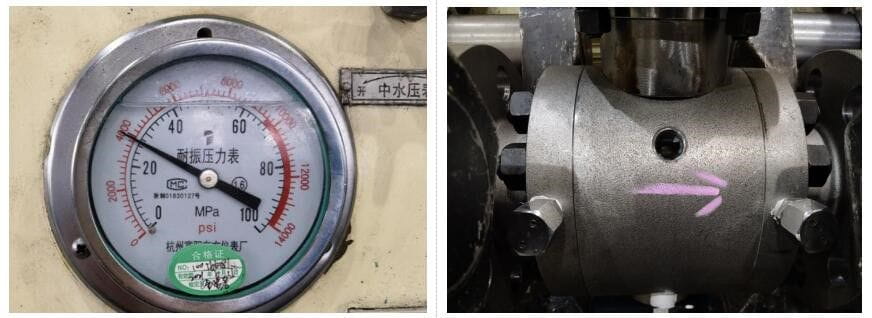

Witnessing Tests

Coat Thickness Check

Packing

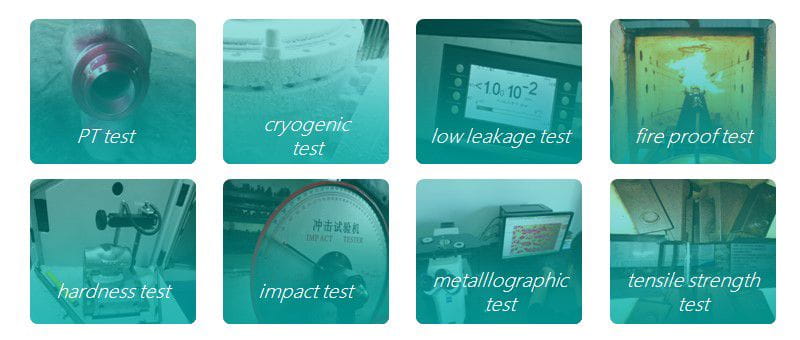

Special Tests

Besides general tests we will do (hydraulic and air test), we could also do tensile strength test, metallographic test, fugitive emission test, and NDE test (UT, RT, PT, MT) upon customers' specific requests.

Detail Information

| Type | Ball Valve |

| Size | 2 Inch |

| Pressure | Class 1500 LB |

| Construction | Trunnion-mounted, Three-Piece Type, Full Bore |

| Connection | RTJ |

| Operation | Gear Operated |

| Body Material | ASTM A105 |

| Design & Manufacture | API 6D |

| Face to Face | ASME B16.10 |

| End Connection | ASME B16.5 |

| Test & Inspection Code | API 598 |

| Fire Safe | API 607 |

| Temperature Range | -29℃ - 120℃ |

| Medium | Water, Oil and Gas |

| Origin | China |

Features

1. EMERGENCY STEM SEALANT INJECTION

This standard feature allows the valve's stem housing to be adapted with a grease fitting to inject sealant during emergency scenarios, providing protection against unplanned spikes in operating conditions.

2. DRAIN AND VENT PORTS

Drain ports located at the bottom of the valve release any fluid trapped in the body cavity of a closed valve. Vent ports located at the top of the body cavity eliminate any gas trapped in the body cavity of a fully closed valve. Both play a key safety role in the double block and bleed and/or double isolation and bleed valve configurations.

3. FIRE SAFE DESIGN

Metal seat design provides a fire-safe shut-off per API 607. Additionally, graphite body seals and flexible graphite packing prevents leakage through the body joints and stuffing box, respectively.

4. ANTI-STATIC DEVICES

Standard anti-static devices ensure electrical continuity between the ball, stem, and body, eliminating the possibility of sparks within the valve created by static electrical charges.

5. VALVE POSITION INDICATION

Clear stamping on the outer diameter of the mounting flange identifies the open or closed position of the valve based on the stem key orientation.

6. BLOWOUT-PROOF STEM DESIGN

Valves are designed with stem/body connection preventing stem blowout under line pressure.

Keywords of ASTM A105 Trunnion Mounted Ball Valve, API 6D, 2 Inch, 1500 LB

API6A Certificated Ball Valves

Ball Valve 2Inch

Ball Valves for Water